Yaskawa implements a solution for Hospital Metalcraft Ltd in record time

System-relevant welding robot MOTOMAN AR2010

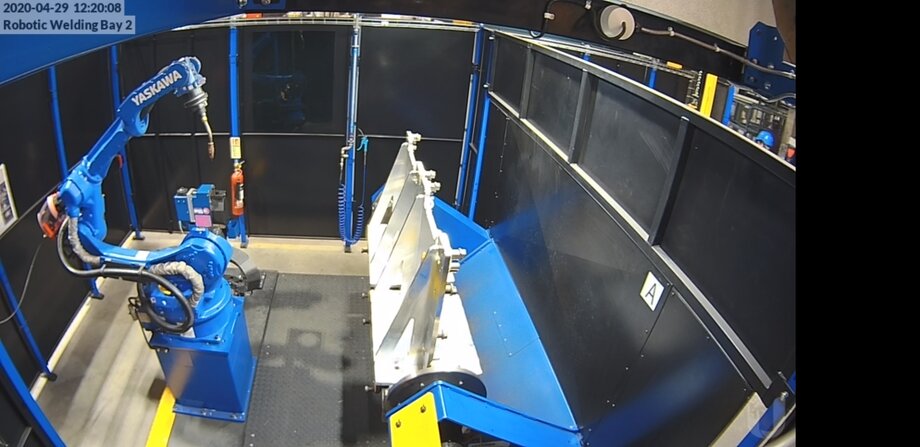

From infusion stands to Caretray trolleys, the hospital furniture and equipment manufactured by Hospital Metalcraft Ltd in Dorset, England, under the brand name Bristol Maid is an integral part of the health & social care supply chain of the National Health Service (NHS) – and currently in high demand. High priority was given to a recent increase in short term production capacities, specifically for a newly developed pump stand with a new robot welding cell. Yaskawa succeeded in implementing an appropriate solution in record time.

- Industries

- Métallurgie

- Applications

- Soudage à l'Arc

- Client

- Hospital Metalcraft Ltd

- Produit

- AR2010 - Série AR

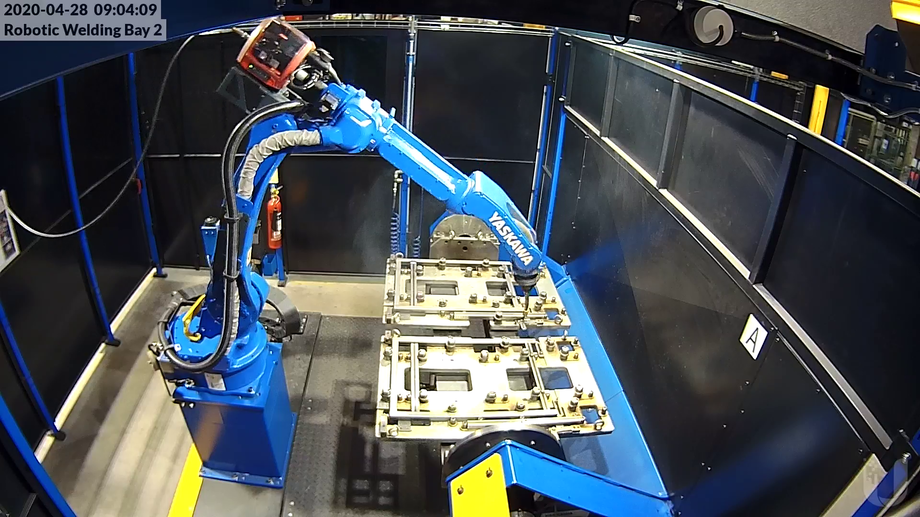

In only four weeks – less than a third of the usual lead time –Yaskawa engineers were able to plan and implement a complete application-specific robot welding cell.

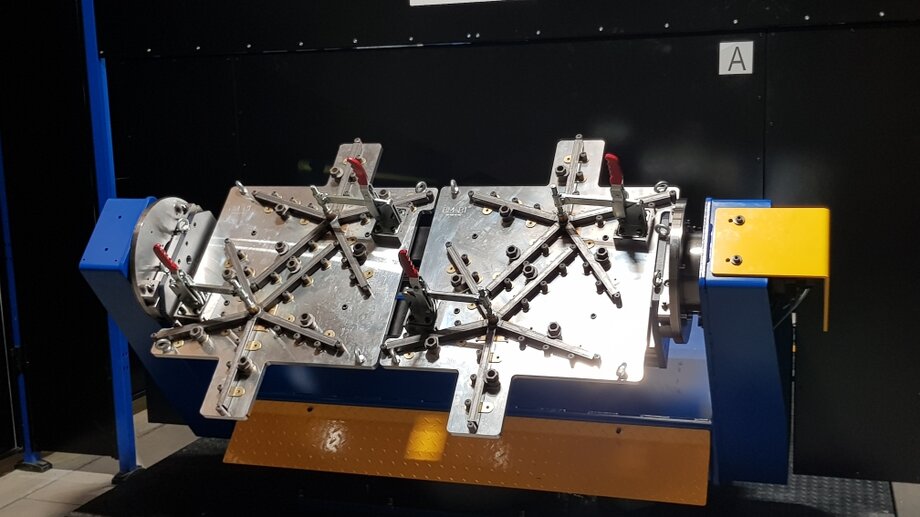

The necessary prerequisites were created by a cooperative agreement with a local system partner and Austrian welding specialist Fronius. Furthermore, with its own European system construction facilities in Germany, Slovenia and Sweden, Yaskawa was able to ensure short supply chains. The contract encompassed all services from one source: from planning, development and construction of the fixtures via positioner and robot programming to turnkey start-up.

Hospital Metalcraft and Yaskawa have been linked by a successful cooperation for many years. It was clear to all involved that the latest order would have to be expedited: “Yaskawa offers a broad range of robot systems, and when we were asked to participate in this important project within a tight schedule, we were only too pleased to accept the challenge,” says Jonny Grey, Sales and Marketing Manager for the UK.

The MOTOMAN AR series of welding robots

The core element of the cell is a high-performance welding robot from the MOTOMAN AR series. The MOTOMAN AR2010 distinguishes itself by a wide working range of 2,010 mm and its high payload of up to 12 kg makes it ideal for welding large and bulky components.

Yaskawa’s fast and accurate AR series of 6-axis robots was especially developed for the exacting demands in the field of arc welding. They enable shorter process times for the user, resulting in increased efficiency and energy savings. Due to their slim build, the flexible and extremely fast manipulators have a small footprint and can be set up in the smallest of spaces. With the introduction of robots, it has been possible to realise integrated manufacturing concepts for optimum process times and a high level of efficiency in production.