Masters in pressure management

Za-Tech was born in 2003 in Montebellunese. Combining the experiences of the two owners in the mechanical and electronic construction sector, it specializes in the production of mechatronic solutions, also highly customized, of which it takes care of all the development phases with the explicit aim of creating machines that no longer have - during their whole life - the need to go back to being the object of interventions by Za-Tech staff.

- Client

- Za-Tech S.R.L.

The challenge

The reasons that are driving the replacement of hydraulic mechanisms with electric motors are many. In addition to a lower risk of dripping and consequent pollution of surfaces with oily liquids that pose a problem for the quality of machining, they are also a problem for the safety of operators. But the most obvious differences are undoubtedly related to greater machining precision, combined with the system's greater versatility in generating special cycles that can be easily reset over time through recipe change.

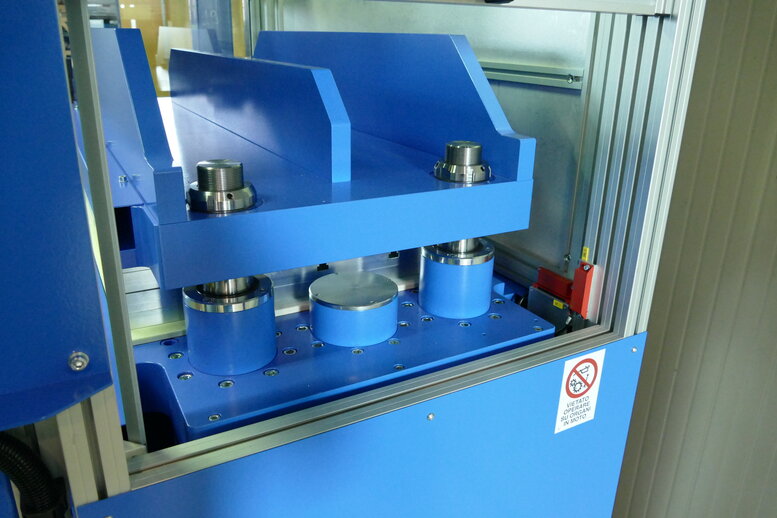

In fact, the company was commissioned to create a machine intended for thermoforming and blanking/die-cutting activities, thus equipped with rather high clamping forces. The need to reach the 50 tons required for the final part of the processing would have been prohibitive with the traditional system, both in terms of motor sizing and speed.

The solution

One element that unites almost all of the albeit different models of electric presses currently on the market is the operating dynamics, which sees the upper platen being pushed down by a single motorized axis located at the top of the press.

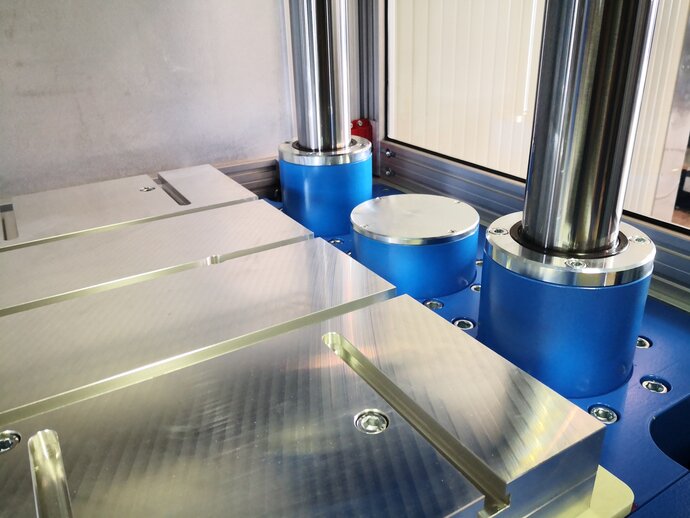

Through collaboration with Erregiemme and Yaskawa engineers, Za-Tech has developed a solution that revolutionizes this dynamic. In it, in fact, it is the upper platen that is pulled from the bottom by means of a system composed of ball screws and 2 Yaskawa brushless motors that, working together, make it possible to break down previous performace limits. In this way, the machine is able to move at a speed of 220 mm/s a 10 q platen applying a maximum clamping force in excess of 50 t, which can also be managed in partial mode, with centesimal precision and in various steps. These features, combined with the ability to handle both hot platens up to 240° and cold platens, make it an ideal solution for carbon forming, thermoforming and coupling applications between various materials.

Other benefits

The new solution also offers some far-from-insignificant side benefits in terms of noise, which has been reduced to practically zero thanks to the use of special screws with a longer pitch, but especially in terms of safety management. Indeed, the safety module with which the Yaskawa motion solution is equipped ensures extremely high levels of safety without penalizing productivity. When an operator invades the safety spaces by interrupting the light curtains, the system is alerted, but the machining cycle is suspended, not interrupted. The cycle can therefore be resumed from where it was interrupted, without being restarted and preventing the workpiece from directly becoming a scrap.

Energy efficiency is also remarkable: the new machine has a consumption of only 15 percent of that of a standard hydraulic solution, reaching 2A when exerting a pressure of 30 t, compared with 20-25 for the traditional solution.